Kazimierzowska 46/48, 02-546 Warszawa

"There's no such thing as waste

only renewable resources."

We are a technology company committed to providing innovative, sustainable, and profitable solutions to the global waste problem. Our R&D team has over 30 years of experience in developing patented technologies. We create innovations that effectively break down the molecular structure of waste and efficiently convert its components into clean fuels, chemicals, and other valuable resources, all while positively impacting the environment. Our core technology converts non-recyclable plastic waste into liquid hydrocarbons, which can be used as feedstock for plastics or fuel components. As an R&D-driven company, we continue to develop next-generation technologies aimed at addressing other forms of problematic waste.

-

Our goal is to provide solutions that are:

- A cost-effective alternative to incineration and landfilling, encouraging increased recycling.

- Technically scalable, making them viable for both small and large cities, allowing waste to be processed locally and reducing the carbon footprint associated with transporting waste across regions and countries.

- Capable of effectively converting waste to maximize the energy contained within it.

- Designed to minimize by-products, avoiding the creation of additional waste-related problems.

- Viable and sustainable without relying on government subsidies, ensuring stability despite potential policy changes.

- Environmentally positive, contributing to overall sustainability.

- Capable of generating attractive earnings and returns for our customers

OUR MISSION IS TO DEVELOP

THE TECHNOLOGIES THAT

ENABLE THE RENEWAL

OF WASTE INTO VALUABLE

RESOURCES

About us

Founder, Main Shareholder and CEO of Polymers Fraction Technology Sp. z o.o.

Founder, Main Shareholder and Vice President of the Management Board of Polymers Fraction Technology Sp. z o. o.

The Story of Technology

Handerek Technologies has developed a pioneering patented technology that chemically recycles waste plastic into feedstock, which can then be used to produce clean recycled plastics or serve as low-carbon alternative fuels. Our aim is to set the global standard in plastic-to-fuel technology, driving a substantial positive environmental impact by maximising the recycling of waste.

COMBINING BUSINESS EXPERIENCE WITH ENGINEERING INNOVATION, DRIVEN BY A PASSION FOR THE ENVIRONMENT

In 2004, Adam Hańderek observed the escalating environmental problem of plastic waste and began his research and development efforts on thermal and thermo-catalytic processing of waste plastics. Between 2005 and 2017, Adam and his team developed eight research installations on a semi-technical scale, testing various apparatus solutions for the thermal depolymerisation of waste plastics. Many of these innovations have been patented both nationally and internationally.

The research focused on finding an effective method for heating waste plastics while minimising the excessive coking of raw materials in the reactor and producing products with boiling points up to a maximum of 360°C in a single integrated process. In 2014, Adam and his team experienced a paradigm shift, approaching the problem in a radically new way. This led to the creation of a highly efficient reactor, free from the by-product waste issues that plagued other technologies. This innovative solution was patented in Poland in 2017, with international patent protection also pursued in the same year.

In 2016, Adam’s work caught the attention of Susan Kim-Chomicka, a serial entrepreneur with global experience and a strong passion for the environment and social impact. Impressed by the technology’s potential environmental benefits, as well as the dedication of Adam and his team, she joined the project as an advisor and investor, helping to fund further research. A research installation was established through a contract with the PIMOT Automotive Industry Institute, where extensive testing confirmed the assumptions of the process using batch technology. Further optimisation of the process followed, leading to the submission of an additional patent application in 2017. The registration of this application allowed the invention to be showcased at an international inventions fair, where it underwent global evaluation.

The Company, Received

Numerous Awards For

Achievements In Innovation:

- iENA Nuremberg, Germany, 2017 – Grand Prix.

- INNOVA in Barcelona, Spain, 2017 – Gold Medal with Distinction and Grand Prix in the category of industrial inventions.

- ARCHIMEDES in Moscow, Russia, 2017 – Gold Medal with Distinction and the Cup of the Union of Engineers and Inventors of Russia.

- INTARG in Katowice, Poland, 2017 – Platinum Medal, Grand Prix INTARG, Cup of the President of NOT (Polish Federation of Engineering Associations), and an individual award for Adam Hańderek – “Leader of Innovation” in the Personality category.

- Belt & Road Initiative Innovation Fair in Chengdu, China, 2016 – Grand Prix and Star of Business Start-up.

Łukasiewicz Research Network

Automotive Industry Institute

Handerek Technologies has signed a research and development cooperation agreement with PIMOT aimed at developing waste processing technologies.

DR ANNA MATUSZEWSKA Ph.D. Eng.

Dr Matuszewska specialises in research within the fields of tribochemistry, fuels, and alternative fuels, including those derived from waste materials. She graduated in 1993 from the Faculty of Chemistry at the Warsaw University of Technology. In 2008, she obtained her PhD in the discipline of Construction and Operation of Machines from the Faculty of Mechanical Engineering at the Cracow University of Technology. Until 2007, Dr Matuszewska worked at the Institute for Sustainable Technologies – National Research Institute in Radom, where her work focused on chemical phenomena occurring in friction nodes, among other areas.

PROF. KRZYSZTOF BIERNAT Ph.D. Eng.

Prof. Biernat is a licensed expert in the field of fuel and energy economy, and a distinguished specialist in the chemical thermodynamics of environmental processes. He is also an expert in the development of technologies, quality evaluation, and the utilisation of operational fluids, including biofuels and biorefinery systems. He serves as a professor at the Automotive Industry Institute (PIMOT), where he is Head of the Department of Fuels and Bioeconomy, and as a lecturer at Cardinal Stefan Wyszyński University. Prof. Biernat is the coordinator of the Polish Technology Platform for Biofuels and a member of the Coordination Committee of the Polish Technology Platform for Bioeconomy.

PROF. ZDZISŁAW CHŁOPEK hab. Ph.D. Eng.

Prof. Chłopek is a distinguished expert in the fields of the construction and operation of industrial machinery and installations, automotive and transport engineering, as well as environmental protection. His research interests focus on issues such as pollution from combustion engines, unconventional fuels, and environmentally friendly solutions in transport. He is a professor at Warsaw University of Technology and at the Institute of Environmental Protection – National Research Institute. Prof. Chłopek is also an expert for the Ministry of the Environment, the Automotive Industry Institute, and the Municipal Transport Chamber of Commerce. He has participated in numerous research projects funded by the State Committee for Scientific Research and the Ministry of Science and Higher Education.

PROF. MACIEJ PACZUSKI Ph.D. Eng

Prof. Paczuski is a renowned specialist in the field of fuels and petroleum technologies. He is the Head of the Department of Chemistry and Organic Technology at Warsaw University of Technology. He also serves on the Supervisory Board of the Automotive Industry Institute and is an expert for the Ministry of Entrepreneurship and Technology. In the past, Prof. Paczuski worked at and managed the Institute of Chemistry at Warsaw University of Technology in Płock on several occasions. He has led numerous research and implementation projects, including those for PKN Orlen. He is the author and co-author of 44 publications, 29 papers, 32 scientific and research papers, and 11 patents and patent applications.

DR ANDRZEJ WOJCIECHOWSKI hab. Ph.D. Eng.

Dr Wojciechowski is a distinguished expert in the fields of machine construction and operation, materials engineering, manufacturing technology, and the properties of construction materials. His research interests also cover transport, vehicle recycling, the recovery of materials from exploitation products, environmental protection, and closed-loop management. He is the President of the Polish Scientific Recycling Association, Director of the Motor Transport Institute, and a professor at the Institute of Precision Mechanics. Dr Wojciechowski is an auditor for the Polish Centre for Testing and Certification and a member of several scientific organisations, including the Polish Society of Ecological Vehicles, the Polish Scientific and Technical Society for Exploitation, and the Polish Society of Materials Science.

Service

Our technology processes waste plastics that are unsuitable for material recycling, such as soiled films, multi-material packaging, all types of consumer packaging, and industrial waste, excluding PVC and PU. Tests were conducted at waste sorting facilities to assess the feasibility of separating the desired types of waste plastics from mixed municipal waste and to establish the appropriate connection between the sorting facility and the waste-to-fuel installation. The tests confirmed the ability to obtain the required raw materials and the possibility of positioning the waste-to-fuel installation directly downstream of the waste sorting process. Our process is not compromised by the permissible ratio of feedstock containing materials typically used in other recycling technologies, such as PET.

TYPE OF PLASTIC WASTE

Our technology processes waste plastics that are unsuitable for material recycling, such as soiled films, multi-material packaging, all types of consumer packaging, and industrial waste, excluding PVC and PU. Tests were carried out at waste sorting facilities to evaluate the feasibility of separating the desired types of waste plastics from mixed municipal waste and to establish the proper connection between the sorting facility and the waste-to-fuel installation. The tests confirmed the ability to obtain the necessary raw material and the potential to place the waste-to-fuel installation directly downstream of the waste sorting process. Our process is not affected by the allowable ratio of feedstock containing materials typically processed by other recycling technologies, such as PET.

FUELING THE CIRCULAR

ECONOMY WITH A TECHNOLOGY

FOR CHEMICALLY RECYCLING

PLASTIC WASTE

STATE-OF-THE-ART TECHNOLOGY OF

WASTE PLASTICS CONVERSION INTO FUELS

1 KG WASTE PLASTICS = 1 L FUEL

Services

Handerek Technologies has developed an advanced technology for the effective and efficient recycling of mixed polymer (plastic) waste, particularly polyolefins (such as polyethylene (PE), polypropylene (PP), and polystyrene (PS)). Following recycling, the end product is a liquid hydrocarbon, which can be used either as a feedstock for producing clean recycled plastics or as a component for EU-standard fuels, including diesel, petrol, and jet fuel.

KEY FEATURES:

- Unwashed polyolefin mixes are used as feedstock.

- High recycling efficiency, ranging from 83-90%, depending on the plastic mix.

- Minimal solid by-products – just 1-2% dry carbon coke (a commodity that can be sold).

- The process is designed to operate continuously.

- The process is energy self-sufficient, generating gas and fuel to power its operations.

- Process is energy self-sucient providing gas and fuel used to operate it.

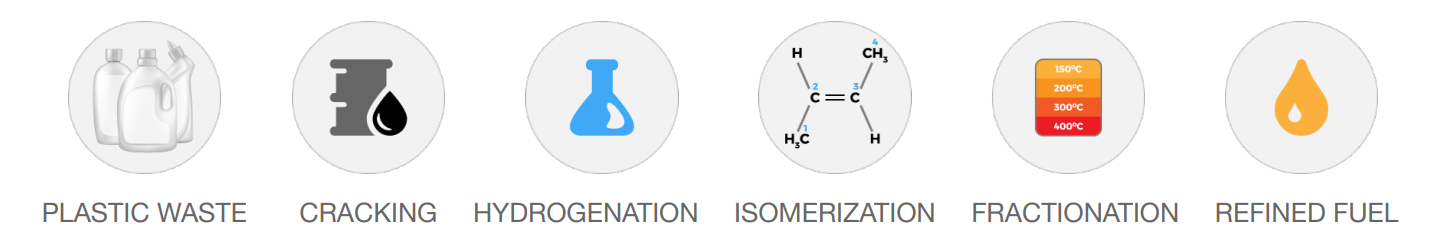

PROCESS STEPS:

1. Sorted post-consumer polyolefin waste plastic is received.

2. The plastics are pre-treated through shredding, screening, and agglomeration.

3. The plastic is then fed into a pre-processing homogenisation device.

4. The pre-processed plastic is directed into a depolymerisation reactor, where a catalytic thermal process breaks down the carbon polymer chains into C1 to C24 hydrocarbon vapours. These vapours can be condensed into ultra-low sulphur clean oil, which can be used for heating, power generation, or marine fuel, or further refined in the enrichment process.

5. The vapour travels to the hydrotreatment reactor, where it undergoes hydrogenation and isomerisation under atmospheric pressure before being condensed.

6. The resulting liquid hydrocarbons are then fractionated by boiling point to produce various products, such as naphtha and diesel. These can be used as feedstock for recycled plastics or as low-carbon alternative fuels, which can be blended with traditional fuels derived from crude oil.

TESTED, AWARDED AND PATENTED

- The process, end products, and emissions have been tested by the PIMOT Automotive Industry Institute.

- Patent granted in 2017, with a second patent awarded in 2019.

- Grand Prix and Gold Medals have been awarded at Europe's largest innovation and technology fairs: iNEA, INNOVA, ARCHIMEDES, and INTARG.

BENEFITS:

- The end product is a fuel of high quality, compliant with EU standards:

- diesel

- gasoline fraction

- jet fuel fraction

- The process is commercially viable without the need for external subsidies.

- The technology generates revenue, thereby reducing overall waste management costs for local governments and communities.

- Positive environmental impact.

INNOVATIVE TECHNOLOGY:

- A unique technology that directly produces engine fuels meeting EU standards, ready for use or sale.

- Designed for continuous operation.

- The process operates under atmospheric pressure.

- The process is energy self-sufficient, generating gas and fuel for its own operation.

OTHER ADVANTAGES:

- Effective management and recycling of plastic waste.

- Reduction of plastic waste in landfills and the environment.

- Conservation of natural raw materials.

- Increased energy diversification.

- Reduced dependence on crude oil imports.

- Fuel produced with CO2 emissions lower than those from crude oil production.